Typhlography, or tactile graphics for the blind, is a broad section dealing with all kinds of signage and information provision for people with special needs. It includes both small signs (e.g., door plates), plans of buildings or spaces, but also graphics designed to help get an idea and general information about an object (e.g., an object or painting from a museum's collection). It should be noted that, contrary to the name, the simplest plaques of this kind do not contain graphics, but only a verbal description.

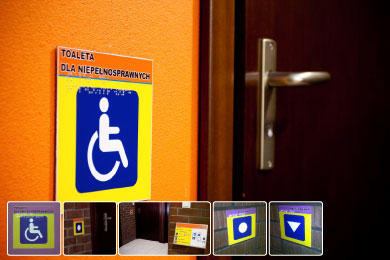

Informational plaques

The purpose of this type of signage is to give the recipient all kinds of information about the purpose, use, history, etc. of a particular place or object. This can be a sign on the door, announcing that behind it is, for example, a restroom or secretariat, but also a plaque or even a large information board describing the depicted object (such as a museum exhibit).

Due to the wide range of applications, many types of plaques can be distinguished, both in terms of the material they are made of and the functions they serve.

Let's start with the material. The simplest placards, usually used to describe the premises, are those made of metal. This type of signage often contains only information in Braille, but sometimes also information (inscription or pictogram) for the sighted. Plaques are made of steel (in natural color) or aluminum (in gold or gray). They are often placed above doorknobs to make it easier for the blind to find them. A specific type of such plates is bent overlays for stair railings. Due to the properties of the material, they are made only of steel.

Metal plates are very thin, measuring about 0.5-0.6mm.

Another material, which gives much more possibilities, is plastic. We make plaques from PMMA. It can be colored, usually used for plaques with Braille alone or additionally with a short inscription for the sighted, or transparent. In placards with transparent PMMA, a colored subprint is made with an information layer for the sighted, and braille is placed in the main layer. Braille lettering is created by drilling holes, in which braille beads are then placed to form six-point braille characters. This method is very durable and resistant to damage. Color overprinting, on the other hand, makes it possible to choose the right color scheme for the customer, to place logos and other, even quite complex graphics.

Braille inscription can be made of transparent balls, in which case it can be located directly above the inscription for the sighted, leaving it legible, or of colored balls in black or white. Regarding braille, we use the Marburg Medium standard recommended by PZN (Polish Association of the Blind).

Regardless of the material, plaques can contain additional information in the form of a QR code (with metal plaques, we suggest that it should not be too complicated for fear of its readability) or in the proximity wireless communication standard - NFC.

Plates of the above-described types can be mounted with double-sided tape (permanent and the most common method of mounting), glued, screwed or mounted with spacers.

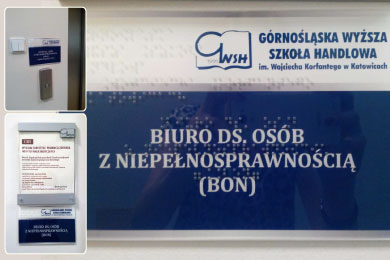

A specific type of the described signs are large information boards. Their manufacturing technology is similar (they are made practically only of plastic), but they differ from small signs in the amount of information they contain. These can be information boards, for example, about the opening hours of a particular office, or let's say an informative description of a building, a work of art, a museum exhibit and the like.

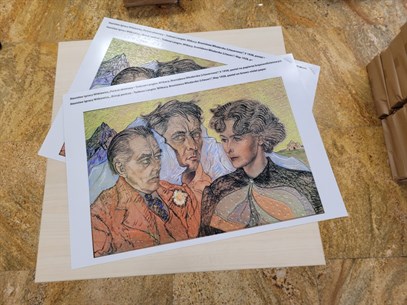

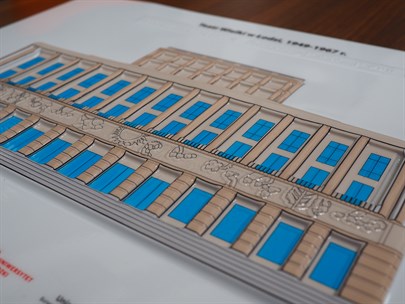

Thermoformed typhlographics

As mentioned in the introduction, typhlography can be used to familiarize the viewer with the appearance of a selected object, animal, painting. Verbal description alone is not always enough, often a very helpful addition is the possibility of touching, feeling a given shape yourself. The best technique for this purpose is convex plastic graphics made by thermoforming. This type of graphics is created by permanently emphasizing under the influence of temperature (and with the help of a previously made matrix) colored (printed) film. The method works best if you want to obtain multiple copies of a given graphic. The typical format of thermoforms is A3, although we can make them in smaller or larger sizes depending on your needs.

Some of our projects:

| 1. The project prepared for the Social Economy Support Center in Walcz |

2. The project prepared for the Silesian University of Technology, Zabrze Division |

3. The project prepared for the Silesian Higher School of Economics in Katowice |

|

|

|

| 4. The project prepared for the Tatra Museum in Zakopane |

5. The project prepared for the University of Lodz |

6. The project prepared for the Polish Theatre in Bielsko-Biała |

|

|

|